Main Parameters:

Insulation class:F Class (155℃)

Rolls: 10mm, 15mm, 20mm, 25mm, 30mm, 50mm width

Thickness:0.23mm,0.26mm,0.29mm

Can be customized

Product Information

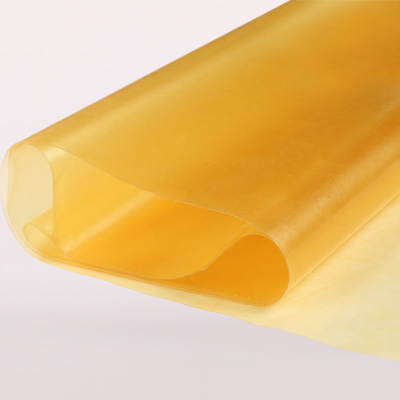

Brief Introduction of the Polyester Shrinking Tape

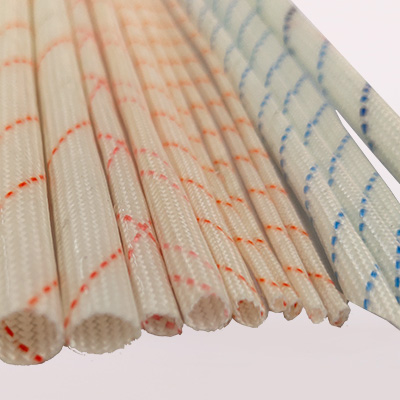

Polyester shrinking tape is made of a special compound fiber of thermal contraction.after binding and dried at 105℃ for 10 minutes,it will be shrunk to 70%,which is good at a solid binding and at a compatibility with transformers.in this way,it will be utilized in the transformer oil at 105℃ for a long time. Cotton tape made of pure cotton or 60%cotton.glassfiber tape made of glassfiber. Used in transformer and electrical motor.

It is a kind of banded-shaped insulation material woven by polyester fiber.

It has heat resistance and insulation property, high heat shrinkage rate, high hot tensile strength, no loose or dropping, and no pollution to the oil.

Main features of the Polyester Shrinking Tape

—Simple, easy to use heat shrink polyester film tape with a wide range of applications.

—High compressive force ensures effective compression, shaping and consolidation.

—Excellent release characteristics from a wide range of materials.

—Significantly improve the product performance and overall quality level of the transformer.

—High insulation level, good electrical performance; dielectric constant 3, between oil and cardboard, super stable and low loss.

—The heat shrinkage is up to 30%, and the binding is firm and durable, without rebound or slack.

—The tensile strength is high, and the mechanical strength is more than tens of times that of cloth tape.

—Pure chemical substances, no burrs, off-line, markings and other defects on the outside, and no dirt and other substances harmful to electrical insulation.

—It has been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Item | Unit | Index Value | |||

| Nominal thickness | mm | 0.2 | 0.25 | 0.3 | |

| Width deviation | mm | ±1 | |||

| Shrinking rate | % | ≥30 | |||

| Tensile Strength | N/10mm | ≥200 | |||

| Cracked ends | Single root | mm | ≥200(no) | ||

| Double root | ≥30(no) | ||||

| Bad side | — | Unaffected loose edges, tight edges, loose edges, thick edges | |||

| Inclusion | — | None inclusion | |||

| Stains | — | No rust, the sum of the length and width of oil ≤14mm | |||

| Broken head | — | Allow each dish to have two segments, each length ≥ 3m | |||

| Hole | — | At the same time, there can be no latitude and longitude fracture Or juxtapose more than 3 holes | |||

| Storage period | month | The date from the factory is 12 months, and it is tested according to product standards for more than 12 months. | |||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

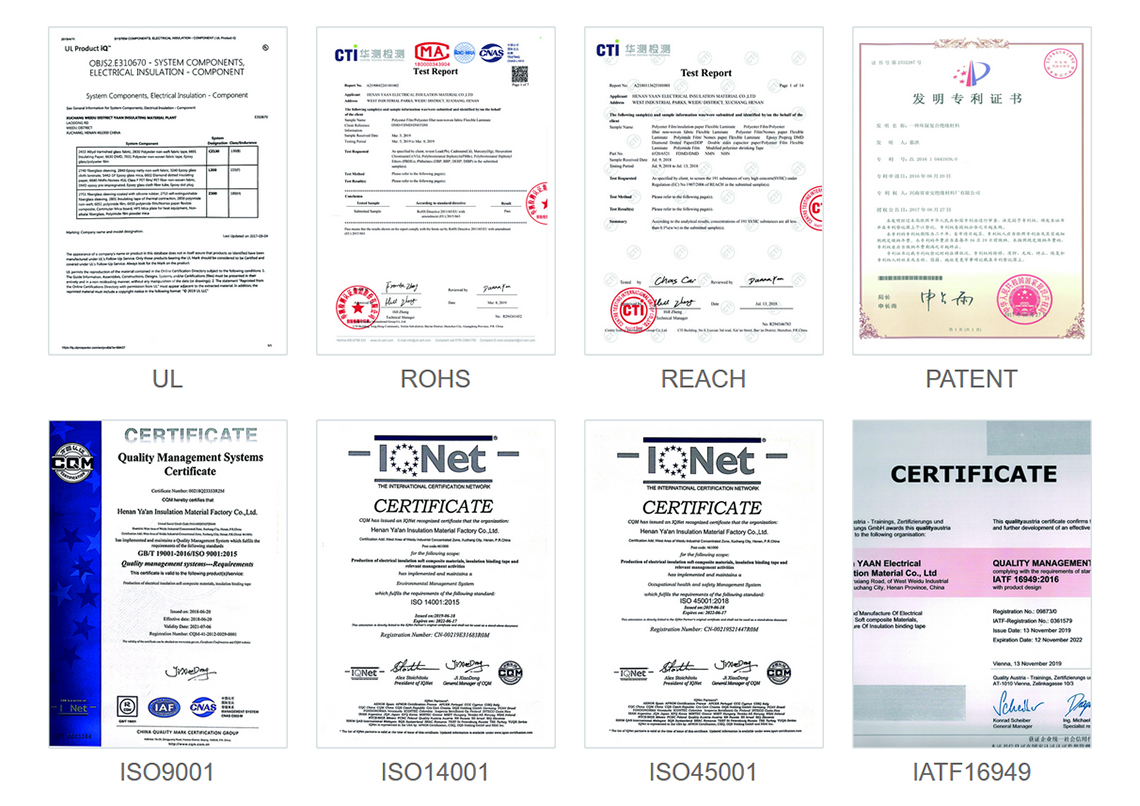

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates