Main Parameters:

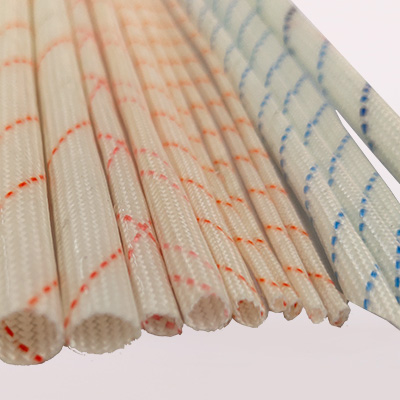

Model: 2715

Insulation class: A class (105 °C)

Line color: Blue, green and pink.

Inside diameter: 1-35mm

Voltage:1.5kv,2.5kv,4kv

Product Information

Brief Introduction of 2715 PVC Coated Fiberglass Sleeve

PVC coating fiberglass sleeve is E-glass fiber braided sleeving coated with polyvinyl chloride resin.

It has excellent softness and elasticity as well as good dielectric properties and chemical resistance.

PVC Coated Fiberglass Sleeve Features:

—High temperature, abrasion and oil resistant

—Resists fraying, bending and knotting

—Woven fiberglass braid impregnated with a heat resistant, extremely tough and flexible plastic insulation

—Compatible with all insulation and conductor types

—Treated to remove all organic matter and resist fraying

—Non-corrosive and has extremely high fungus resistance

—It has been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Properties | Unit | Value | |||||||

| Appearance | / | The coating should be uniform and the surface should be smooth, with no | |||||||

| defects affecting the product performance. | |||||||||

| Inner diameter and wall thickness | mm | Inner diameter | Wall thickness | ||||||

| Tolerance | Type 406 | Type 407 | |||||||

| Standard | Two- | One- | Min | Max | Min | Max | |||

| way(±) | way(+) | ||||||||

| 1 | 0.15 | 0.3 | 0.25 | 0.9 | 0.2 | 0.75 | |||

| 1.5 | 0.15 | 0.3 | 0.35 | 0.9 | 0.2 | 0.75 | |||

| 2 | 0.2 | 0.4 | 0.35 | 0.9 | 0.2 | 0.75 | |||

| 2.5 | 0.2 | 0.4 | 0.4 | 0.9 | 0.2 | 0.75 | |||

| 3 | 0.25 | 0.5 | 0.4 | 0.9 | 0.2 | 0.75 | |||

| 4—6 | 0.25 | 0.5 | 0.5 | 0.9 | 0.3 | 0.75 | |||

| 8 | 0.5 | 1 | 0.5 | 1.2 | 0.3 | 0.9 | |||

| 10—25 | 0.5 | 1 | 0.65 | 1.2 | 0.4 | 0.9 | |||

| Breakdown voltage | Value | KV | Pellet slot or straight core bar/100mm foil electrode | Mid-value | Minimum value | Mid-value | Minimu m value | ||

| Under room | 5.7 | 4.3 | 3.5 | 2.5 | |||||

| temperature | |||||||||

| Under high | ≥ | 2.6 | 2 | 1.5 | 1.2 | ||||

| temperature | |||||||||

| After hot and humid | 2.5 | 2 | 1.8 | 1.2 | |||||

| Insulation resistance | Under room temperature | Ω | — | ≥1.0×109 | ≥1.0×109 | ||||

| After hot and humid | ≥1.0×108 | ≥1.0×108 | |||||||

| Fire spreadability | Burning | S | ≤60 | ||||||

| time | |||||||||

| Visual | — | The indicator flag should not burn on any of the three specimens. Nor should | |||||||

| inspection | the cotton be ignited by ignited or burning particles or by ignited drops. | ||||||||

| Soldering heat resistance | — | Pass (Only for sleeve with nominal inner diameter ≤ 5 mm) | |||||||

| Bending after heating | The coating has no visible cracks or peeling off, allowing the color to become darker (test temperature: 130±2℃,exposure time:96±1h) | ||||||||

| — | |||||||||

| Bending at low | — | The coating has no visible cracks or peeling off (test temperature: ≤-25±2℃) | |||||||

| temperatures | |||||||||

| Resistance to mold growth | — | Level 1 or better | |||||||

| Shelf life | — | 12 months | |||||||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

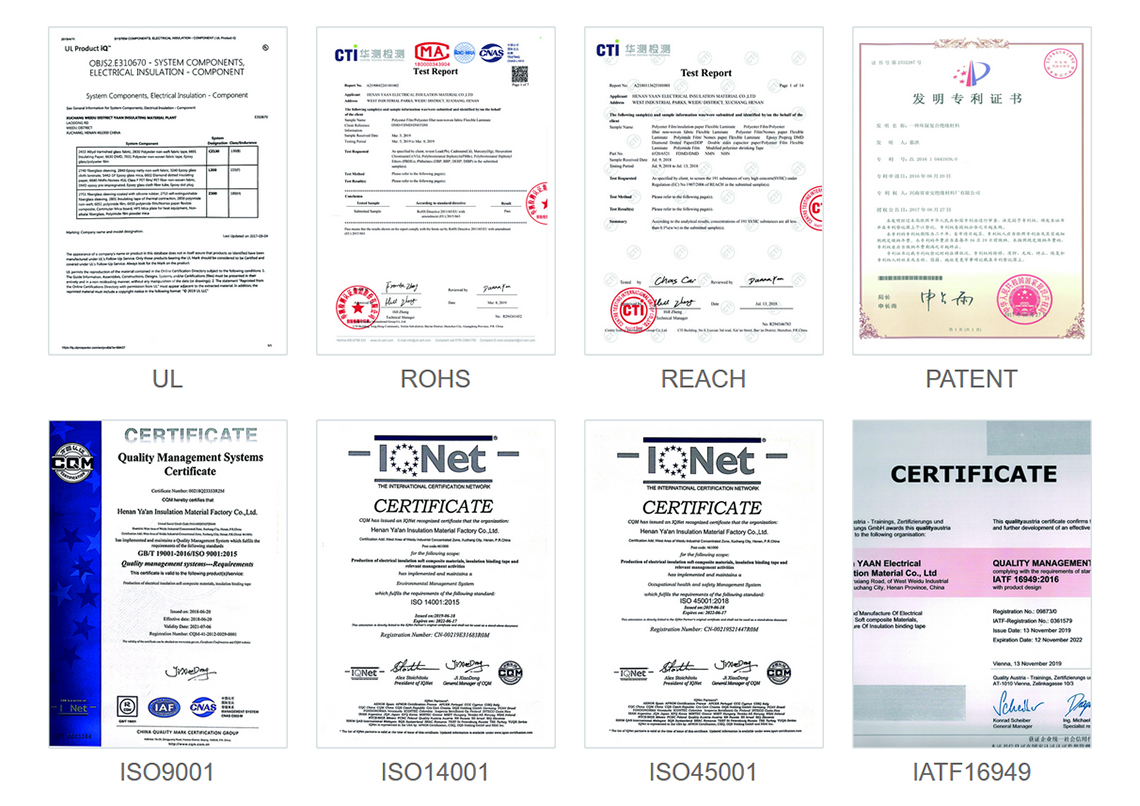

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates