Main Parameters:

Insulation class:C Class (200℃)

Rolls: 12mm-200mm width

Thickness:0.10mm

Can be customized

Product Information

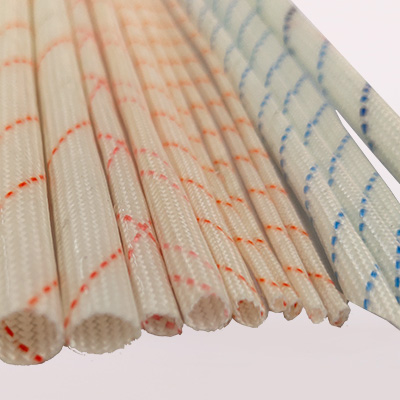

Brief Introduction of the Non-alkali Fiberglass Tape:

Non-alkali fiberglass tape has flame retardancy, high temperature resistance, good insulation, good corrosion resistance, less moisture absorption and strong pulling resistance.

Non alkali Fiberglass tapes for winding motors, transformer is made of the non-alkali glass fiber yarns. The main component is E-glass, oxidation potassium, oxidation sodium, of which the content of oxidation of alkli metals is no more than 0.5%.

This product has good thermal resistance, excellent insulating, corrosion resistance.

Main advantages of the Non-alkali Fiberglass Tape

—High temperature resistance

—Good electrical insulation properties

—Excellent mechanical strength

—Fiber glass tape is pliable and tacky.

—Its web structure provides easy unwind without glass strands separation an overlapping.

—The product contributes the characteristics of high tensile strength, high resistance to shocks, high modulus of elasticity, dimensional stability as well as no magnetically confining and eddy currents losses.

Specifications:

Insulation class:C Class (200℃)

Rolls: 12mm-200mm width

Thickness:0.10mm

Technical Parameters

| Item | Unit | Value | ||

| Thickness | Nominal value | 0.12 | 0.15 | |

| Deviation | mm | ±0.012 | ±0.015 | |

| Width and deviation | ≤25 | ±1 | ||

| ≥25 | mm | ±2 | ||

| Density | Warp direction | 27±1 | 27±1 | |

| Across warp | Pcs/10mm | 15±1 | 15±1 | |

| Breaking strength | N/20mm | ≥400 | ≥540 | |

| Broken-ends | Single broken-ends | mm | ≤100 | |

| Double broken-ends | ≤30 | |||

| Bad side | — | No loose edges, tight edges, open edges, thick edges that affect the use | ||

| Inclusion | — | No inclusions | ||

| Stains | — | No rust, the sum of length and width of oil stain≤14mm | ||

| Alkali metal oxide | % | ≤0.8 | ||

| Storage requirements | Should be stored at temperatures not exceeding 40 ℃, | |||

| dry, clean and well-ventilated warehouse, not be near the fire source, heating. | ||||

| Storage period | month | Shelf life is 12 months. Over 12 months according to the product standard inspection, qualified can still be used. | ||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

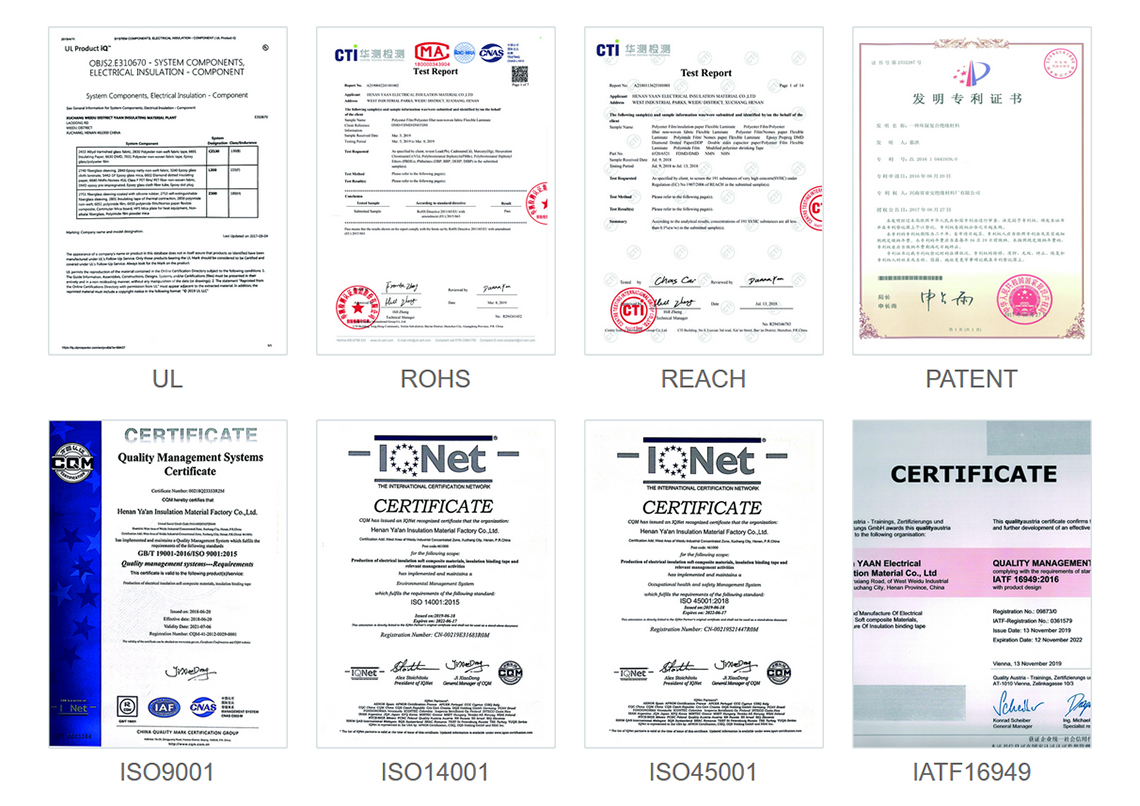

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates