Main Parameters:

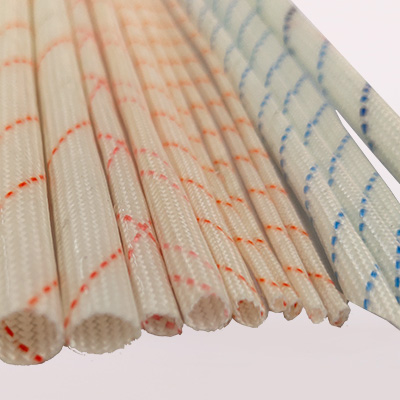

Model: 2740

Insulation class: F class (155 °C)

Color: Red, white, black,etc

Inside diameter: 1-35mm

Voltage:1.5kv,4kv.

Product Information

Brief Introduction of Acrylic Coated Fiberglass Sleeve

Acrylic coated fiberglass sleeve is E-glass fiber braided sleeving coated with a layer of acrylic resin.

It is a carefully engineered, high dielectric sleeving, having an initial average dielectric of 7 kV and a 1/32" wall outer layer of unsaturated glass, braided over and bonded to the acrylic sleeving.

It is a heat-treated, tightly braided fiberglass sleeving coated with a dielectric acrylic resin. This durable sleeving will withstand mechanical stress and holds it’s dielectric strength on all bends.

It is extremely flexible and easily installed. It is used in electrical apparatus such as electric motors, transformers, generators, home appliances, lighting fixtures, instrument circuits and controls, switchgear, breaker panels, welding equipment.

Main advantages of the Acrylic Coated Fiberglass Sleeve

—Acrylic resin continuously coated over premium electrical grade braided fiberglass sleeving.

—Excellent flexibility, cut-through and mechanical abrasion resistance

—Rated class 155ºC electrically.

—Compatible with all magnet wire coatings as well as insulating varnishes such as polyesters, epoxies, phenolics and formvar

—Approved component in most UL insulation systems.

—Made from Clear, modified acrylic resin which offers increased mechanical strength and improved thermal stability.

—It has been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Properties | Unit | Value | |||||||

| Appearance | / | The coating should be uniform and the surface should be smooth, with no | |||||||

| defects affecting the product performance. | |||||||||

| Inner diameter and wall thickness | mm | Inner diameter | Wall thickness | ||||||

| Standard | Tolerance | Type 403 | Type 404 | ||||||

| Two-way (±) | One-way (+) | Min | Max | Min | Max | ||||

| 1 | 0.15 | 0.3 | 0.25 | 0.75 | 0.2 | 0.75 | |||

| 1.5 | 0.15 | 0.3 | 0.35 | 0.75 | 0.2 | 0.75 | |||

| 2 | 0.2 | 0.4 | 0.35 | 0.75 | 0.2 | 0.75 | |||

| 2.5 | 0.2 | 0.4 | 0.4 | 0.75 | 0.2 | 0.75 | |||

| 3 | 0.25 | 0.5 | 0.4 | 0.75 | 0.2 | 0.75 | |||

| 4—6 | 0.25 | 0.5 | 0.5 | 0.75 | 0.3 | 0.75 | |||

| 8 | 0.5 | 1 | 0.5 | 0.75 | 0.3 | 0.75 | |||

| 10—25 | 0.5 | 1 | 0.65 | 1.2 | 0.4 | 0.9 | |||

| Breakdown voltage | Value | KV | Pellet slot or straight core bar/100mm foil electrode | Mid-value | Minimum | Mid-value | Minimum | ||

| value | value | ||||||||

| Under room temperature | 5.7 | 4.3 | 3.3 | 2.5 | |||||

| Under high | 2.9 | 2.3 | 1.9 | 1.4 | |||||

| temperature | ≥ | ||||||||

| After hot and | 1.7 | 1.3 | 1.4 | 1.1 | |||||

| humid | |||||||||

| Insulation resistance | Ω | — | ≥1.0×109 | ||||||

| Fire spreadability | Burning time | S | ≤60 | ||||||

| Visual inspection | — | The indicator flag should not burn on any of the three specimens. Nor should the cotton be ignited by ignited or burning particles or by ignited | |||||||

| drops. | |||||||||

| Soldering heat resistance | — | Pass (Only for sleeve with nominal inner diameter ≤ 5 mm) | |||||||

| Bending after heating | The coating has no visible cracks or peeling off, allowing the color to | ||||||||

| — | become darker (test temperature: 180±3℃) | ||||||||

| The coating has no visible cracks or peeling off (test temperature: ≤-15~ | |||||||||

| Bending at low temperatures | — | -18℃) | |||||||

| Hydrolysis resistance of paint | There is no migration of the coating, no adhesion between the hose and | ||||||||

| layer | — | the paper and the hose test piece, and no discoloration of the paper. | |||||||

| Shelf life | — | 12 months | |||||||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

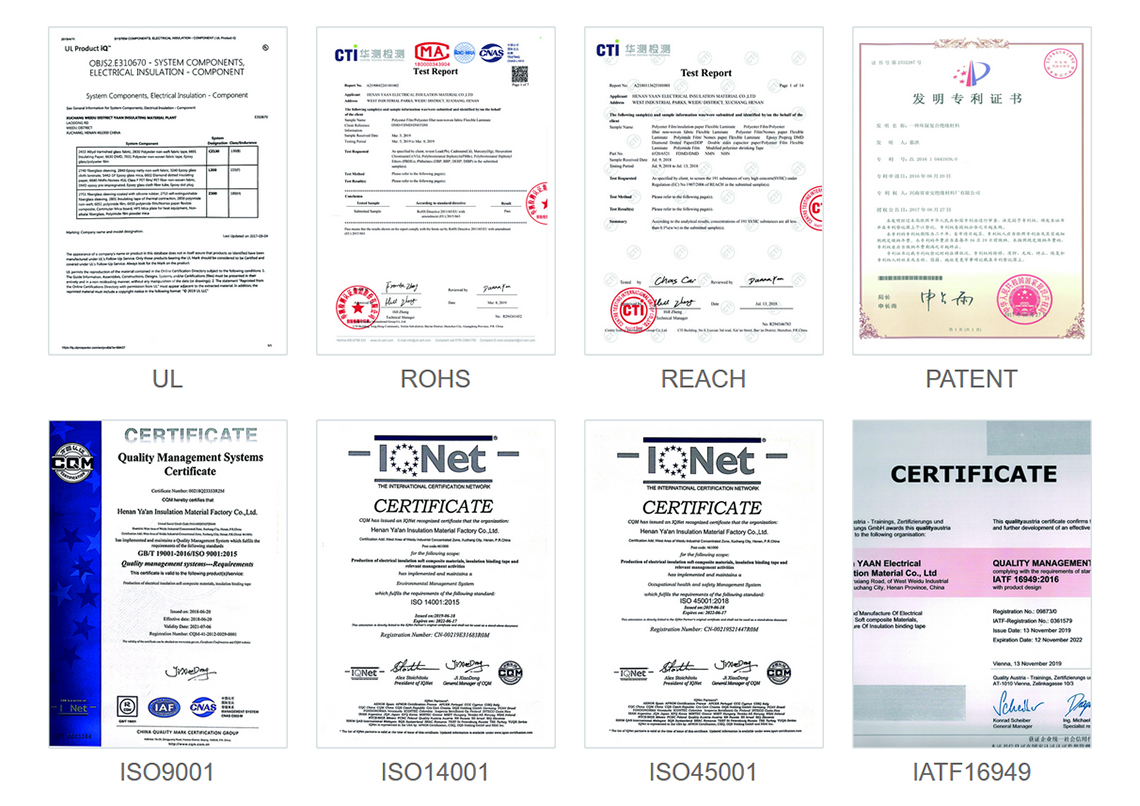

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates