Main Parameters:

Insulation class: H class (180 °C)

Length: Regular 1m (customized length)

Pipe Diameters: 4*8*1000/8*14*1000/10*20*1000

The product’s diameter are negotiable

Product Information

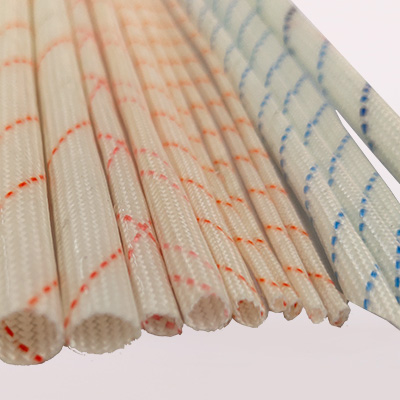

Brief Introduction of the Insulation Crepe Paper Tube

Crepe paper tube are made of electric paper wrinkled with insulating paper, and are mainly used for the insulation wrapping materials of oil-immersed transformer inner wires.

This crepe paper is used as an insulation in manufacture of oil cooled transformers, current transformers of types IMB, CT, CVT, etc. as leads and shields.

This crepe paper has 300% more strength in mechanical and cross mechanical directions and hence is more resistant to breakage.

It can also take various shapes of the surface being insulated. Crepe paper also has greater surface area which helps to retain more oil and hence lowers the working temperature of the transformer.

Main features of the Insulation Crepe Paper Tube

—Excellent compatibility with liquid di-electrics

—Crepe paper allows maximum retention of oil

—Direction of creping is transverse to tube length

—Bendable under extreme conditions without collapsing

—Insulation class: H class (180 °C)

—Length: Regular 1m (customized length)

—Pipe Diameters: 4*8*1000/8*14*1000/10*20*1000

—The crepe paper tube has been approved by UL (NO.: E310670) ,ROHS and REACH test.

* The product’s diameter are negotiable

Technical Parameters

| Item | Unit | Value | ||||

| Crepe Paper | Thickness | mm | 0.05 | 0.075 | 0.08 | 0.13 |

| Tolerance | 0.35±0.05 | 0.48±0.08 | 0.60±0.10 | 0.80±0.10 | ||

| Ash Content | % | ≤0.7 | ≤0.7 | ≤1.0 | ≤1.0 | |

| Moisture | % | 6.0~9.0 | ||||

| Ether extract | % | ≤0.3 | ≤0.3 | ≤0.4 | ≤0.5 | |

| PH | 6.5~7.5 | |||||

| Pollution Oil | % | <0.1 | ||||

| Tensile Strength | MD | KN/m | ≥1.96 | ≥2.60 | ≥3.0 | ≥3.3 |

| CD | ≥1.30 | ≥1.96 | ≥2.3 | ≥2.7 | ||

| Wrinkle degree | % | ≥50 | ||||

| Breakdown voltage in air | V/layer | ≥950 | ≥1000 | ≥1000 | ≥1000 | |

| Conductivity,water displacing liquid | mS/m | ≤8.0 | ≤8.0 | ≤9.0 | ≤10 | |

| Density | g/m2 | 60±10% | 110±10% | 110±10% | 130±10% | |

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

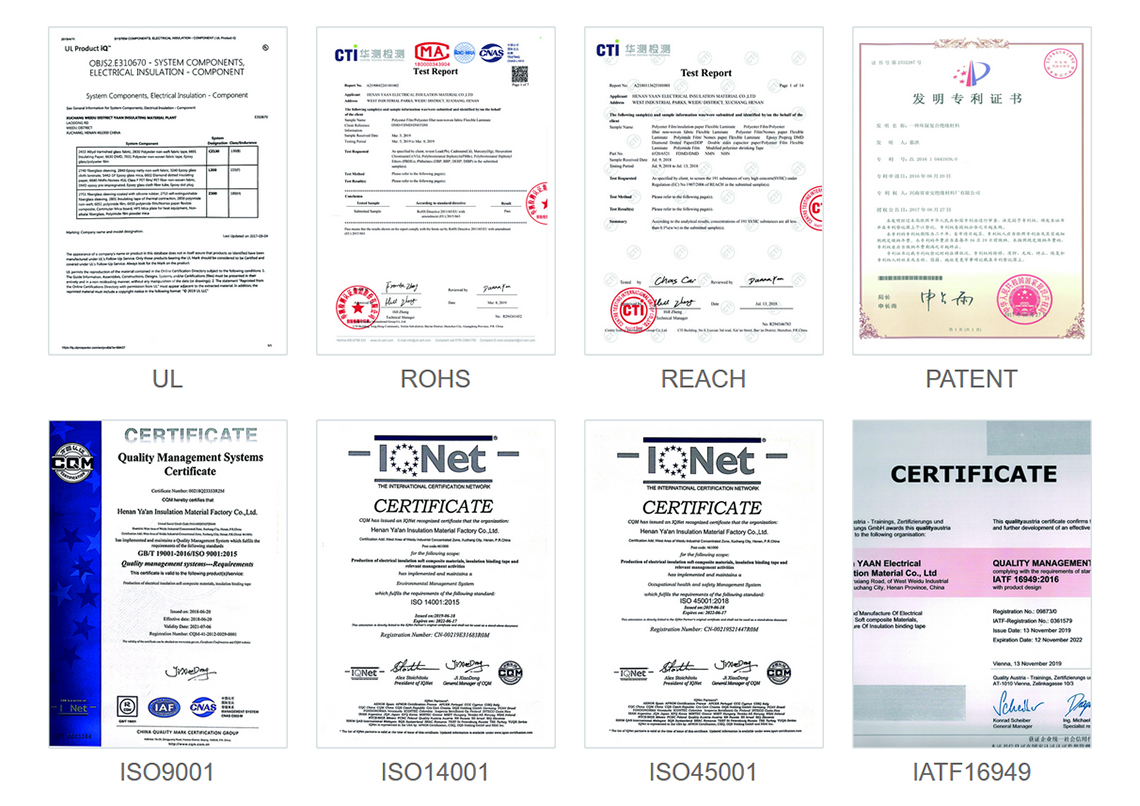

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates