Main Parameters:

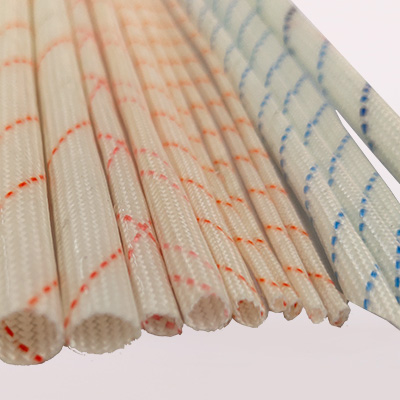

Model: 3240

Insulation class: F class (155 °C)

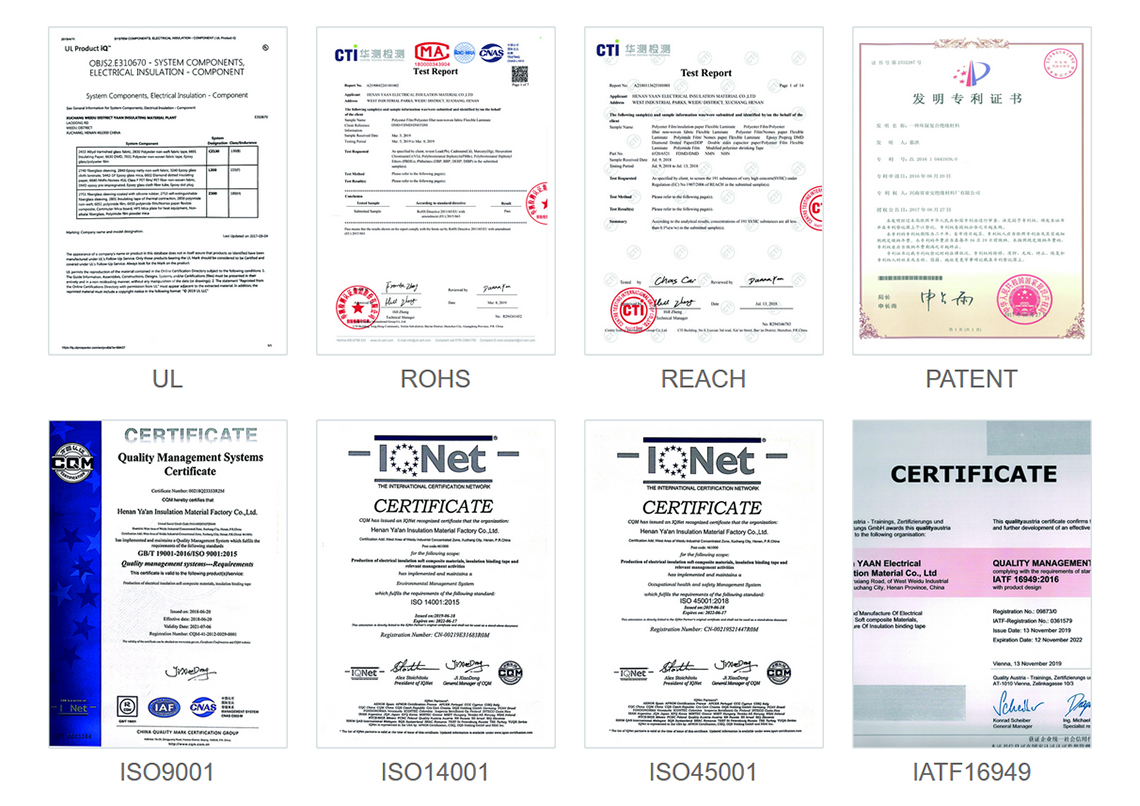

Color: Yellow,special colours can be provided on request.

Thickness:0.3-120mm

Size:980*1980mm,1020*2070mm,1220*2440mm

Product Information

Brief Introduction of the Epoxy Glass Cloth Board

Epoxy glass cloth laminated sheet is made of ethoxyline and glass cloth. It has high dielectric properties, tear strength and tensile strength, good impregnation performance.

It is characterized by excellent mechanical and electrical insulating properties, which keeps even at higher temperatures.

characterized by resistance to tracking.

It is used in the production of components with good mechanical and electrical properties, for electrical equipment at higher temperatures or in humid environments, for stressed electrical insulating components, such as chassis, body equipment, housing parts of distribution boards, transformers, switchgears, electrical machines.

Main Features of the Epoxy Glass Cloth Board

Insulation class: F class (155 °C)

Color: Yellow,special colours can be provided on request.

Thickness:0.3-120mm

Size:980*1980mm,1020*2070mm,1220*2440mm

The 3240 epoxy resin glass cloth laminated sheet has been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Item name | Unit | Index value | |||||

| Nominal thickness and vertical layer direction electric strength | mm KV/mm | Nominal thickness | deviation | Electric strength | Nominal thickness | deviation | Electric strength |

| 0.4 | ±0.10 | 16.9 | 12 | ±0.94 | — | ||

| 0.5 | ±0.12 | 16.1 | 14 | ±1.02 | — | ||

| 0.6 | ±0.13 | 15.6 | 16 | ±1.12 | — | ||

| 0.8 | ±0.16 | 15.2 | 20 | ±1.30 | — | ||

| 1 | ±0.18 | 14.8 | 25 | ±1.50 | — | ||

| 1.2 | ±0.20 | 13.7 | 30 | ±1.70 | — | ||

| 1.5 | ±0.24 | 13 | 35 | ±1.95 | — | ||

| 2 | ±0.28 | 11.8 | 40 | ±2.10 | — | ||

| 2.5 | ±0.33 | 10.9 | 45 | ±2.30 | — | ||

| 3 | ±0.37 | 10.2 | 50 | ±2.45 | — | ||

| 4 | ±0.45 | — | 60 | — | — | ||

| 5 | ±0.52 | — | 70 | — | — | ||

| 6 | ±0.60 | — | 80 | — | — | ||

| 8 | ±0.72 | — | 90 | — | — | ||

| 10 | ±0.82 | — | 100 | — | — | ||

| Vertical layer bending strength(150±3℃) | Mpa | ≥340 | |||||

| Apparent bending elastic modulus | Mpa | ≥24000 | |||||

| Vertical layer compression strength | Mpa | ≥350 | |||||

| Parallel layer impact strength (charpy type) | KJ/m2 | ≥33 | |||||

| Parallel layer impact strength (cantilever method) | KJ/m2 | ≥34 | |||||

| Parallel layer shear strength | Mpa | ≥30 | |||||

| Tensile Strength | Mpa | ≥300 | |||||

| Parallel layer direction breakdown voltage (90℃ in oil) | KV | ≥35 | |||||

| Dielectric constant (50Hz and 1MHz) | — | ≤5.5 | |||||

| Dielectric loss constant (50H and 1MHz) | — | ≤0.04 | |||||

| Insulation resistance after immersion in water | MΩ | ≥5×104 | |||||

| Long-term heat resistance | — | ≥130 | |||||

| Density | g/cm3 | 2 | |||||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates