Main Parameters:

Model: 2753

Insulation class: H class (180 °C)

Color: Blue, green, white,black,red,etc

Inside diameter: 1-24mm

Voltage:1.5kv,2.5kv,4kv,7kv

Product Information

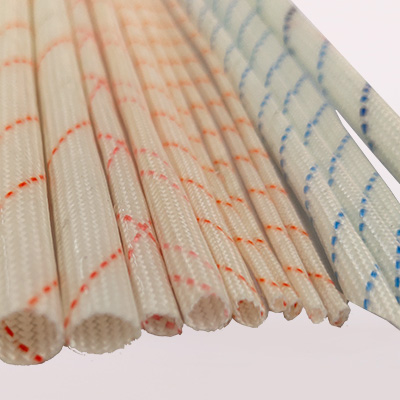

Brief Introduction of Silicone Resin Fiberglass Self-extinguish Sleeve

Silicone resin fiberglass self-extinguish sleeve is non-alkali glass fiber yarn processed by high temperature treatment,then coated with silicone copolymer resin.

The high temperature resistant silicone sleeve is made of alkali-free glass fiber yarn woven into a tube, coated with organic high temperature resistant silicone resin and processed by high temperature.

With flame retardant, thermal insulation, thermal insulation,electrical resistance, softness and other properties. It is mainly used for cable insulation protection in high temperature places such as iron and steel plants, smelters, glass plants, fire fighting equipment, large-scale transformer places.

Characteristics of Silicone Resin Fiberglass Self-extinguish Sleeve

—Temperature class: H grade (180 °C)

—Voltage:1.5kv,2.5kv,4kv,7kv

—Inside diameter: 1-24mm

—High density fiberglass braiding and liquid silicone resin

—Color: Blue, green, white,black,red,etc

— It has been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Properties | Units | Values | |||

| Jan-53 | Feb-53 | Mar-53 | |||

| Appearance | / | white, both of ends are trimmed. the coating is even, continues, adhered to the fiberglass yarn fast. | |||

| Diameter | 1.0-3.5 | mm | 0.3 | ||

| -0.1 | |||||

| 4.0-10 | 0.5 | ||||

| -0.3 | |||||

| Wall thickness | 1.0-3.5 | ≤0.50 | |||

| 4.0-10 | ≤0.70 | ||||

| Breakdown voltage | KV | ≥4.0 | ≥2.5 | ≥1.5 | |

| Time of self-extinguishment | S | ≤10 | |||

| Heat resistance | / | After the sleeving has been treated under temperature of | |||

| 250±5 degree in a cabinet for 24hours, the coating of the | |||||

| sleeving should not appear detached, and discolored. | |||||

| Storage conditions | / | It should be stored in the dry, clean, and good ventilation, | |||

| temperature less than 40℃, no fire warmer, no exposure in sun. | |||||

| Shelf time | / | 6 months | |||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

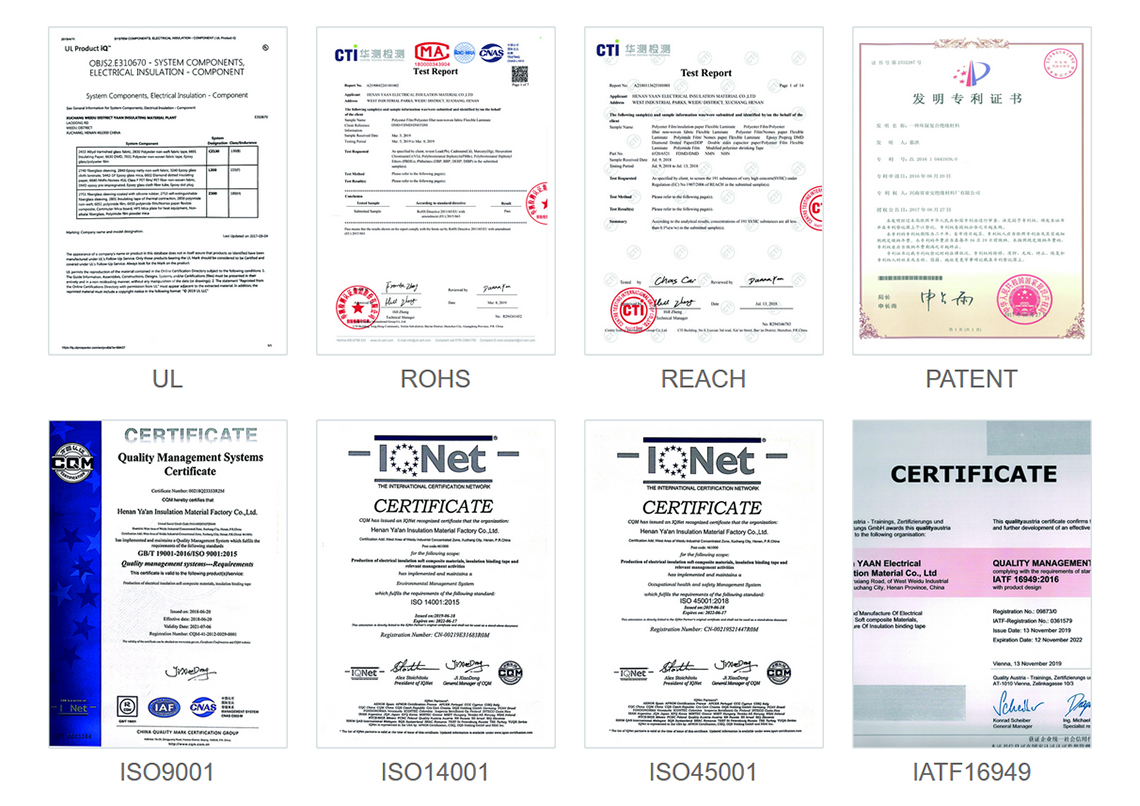

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates