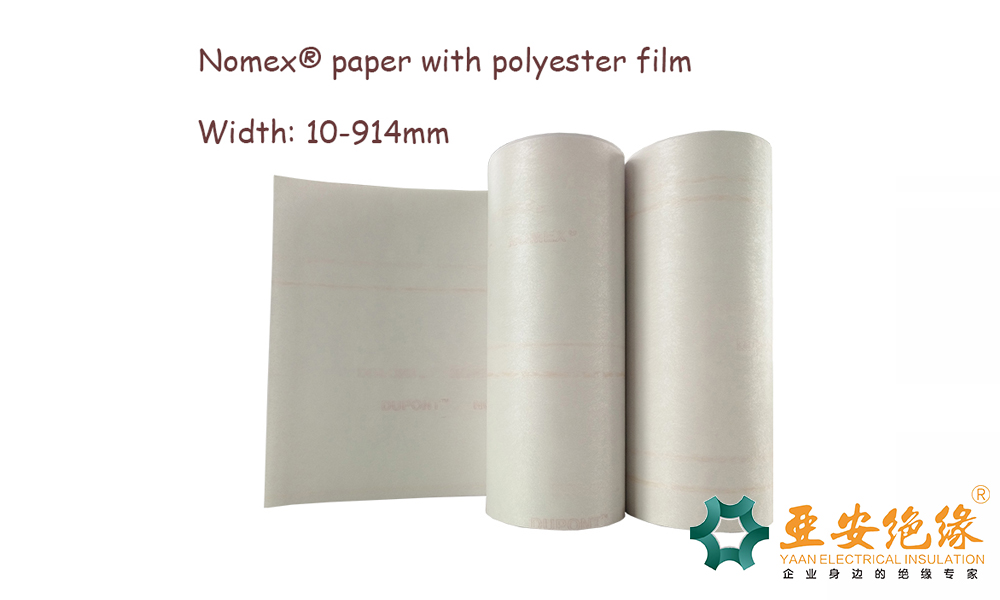

Main Parameters:

Insulation class: F/H class (155/180 °C)

Width: 10-914mm

Thickness: 0.12-0.5mm

Can be customized

Product Information

Brief Introduction of the Nomex insulation paper:

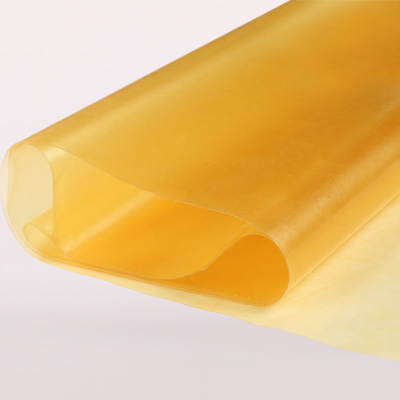

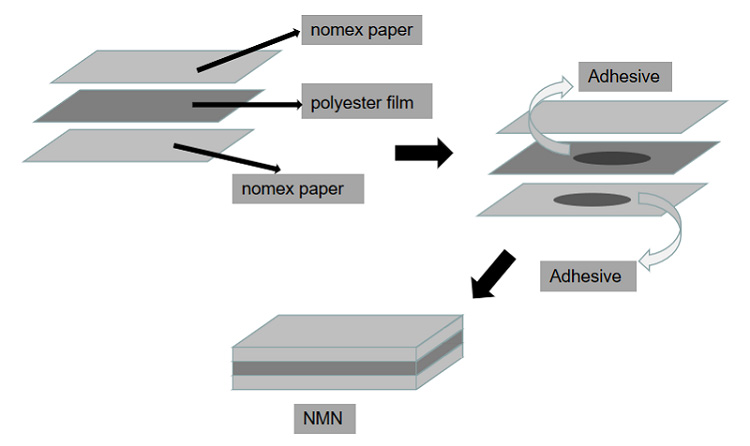

The Nomex insulation paper is a three-ply laminate with polyester film between two layers of Nomex® paper.

About the Nomex paper:

Ideally suited for a variety of temperature ranges and applications, laminate insulation products based on Nomex® paper help enhance the performance and reliability of rotating machines.

About the polyester film: It has excellent mechanical properties, dielectric strength, and dimensional stability, as well as low water absorption, and good resistance to most chemicals. These general purpose films are often used for industrial laminates and electric motor and cable insulation.

The nomex insulation paper laminates made with Nomex® papers are used in UL systems typically up to 180°C. These laminates are broadly used in the production and repair of motors, generators of many sizes and temperature classes. The most important applications for these laminates are slot liners, wedges and phase insulation in Class H motors and generators, as well as in large and specialty Class F motors.

Main characters of this Nomex insulation paper:

1. Temperature F/H class

2. Excellent heat resistance, dielectric properties and mechanical strength.

3 Good cutting resistance, overload resistance, high rigidity, good compatibility with insulating paint

4. The slots, turns and linings of F-class motors and appliances are insulated.

5. Form: roll, sheet, strip

Technical Parameters

| Item | Unit | Requirement | |||||||||

| Nominal thickness | mm | 0.15 | 0.17 | 0.19 | 0.22 | 0.24 | 0.26 | 0.31 | 0.37 | 0.41 | |

| Thickness tolerance | mm | ±0.022 | ±0.024 | ±0.026 | ±0.031 | ±0.037 | ±0.041 | ||||

| Grammage | g/m2 | 150±18 | 170±20 | 200±24 | 230±27 | 270±32 | 305±36 | 360±43 | 450±54 | 515±61 | |

| Film nominal thickness | um | 36 | 50 | 75 | 100 | 125 | 150 | 188 | 250 | 300 | |

| Tensile strength | MD no bending | N/10mm | ≥150 | ≥150 | ≥170 | ≥190 | ≥220 | ≥240 | ≥270 | ≥330 | ≥370 |

| MD after bending | ≥90 | ≥90 | ≥105 | ≥120 | ≥150 | ≥180 | ≥200 | ≥300 | ≥330 | ||

| TD no bending | ≥80 | ≥90 | ≥100 | ≥110 | ≥130 | ≥170 | ≥200 | ≥250 | ≥300 | ||

| TD after bending | ≥70 | ≥70 | ≥90 | ≥100 | ≥120 | ≥150 | ≥150 | ≥200 | ≥230 | ||

| Elongation (%) | MD | % | ≥15 | ≥3 | |||||||

| TD | ≥20 | ≥10 | |||||||||

| Breakdown voltage | No bending | KV | ≥7 | ≥8 | ≥11 | ≥12 | ≥14 | ≥16 | ≥19 | ≥23 | ≥25 |

| After bending | ≥6 | ≥7 | ≥9 | ≥10 | ≥12 | ≥14 | ≥15 | ≥18 | ≥19 | ||

| Delamination | — | No Delamination, no bubble or other defects | |||||||||

| Heat affected (180±2℃) 10min | No Delamination, no bubble, no adhesive flow | ||||||||||

| Long-term heat resistance (temperature index TI) | ≥155 | ||||||||||

| Weight and area conversion | m2/Kg | 7.23 | 6.33 | 5.18 | 4.39 | 3.8 | 3.36 | 2.85 | 2.28 | 1.97 | |

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

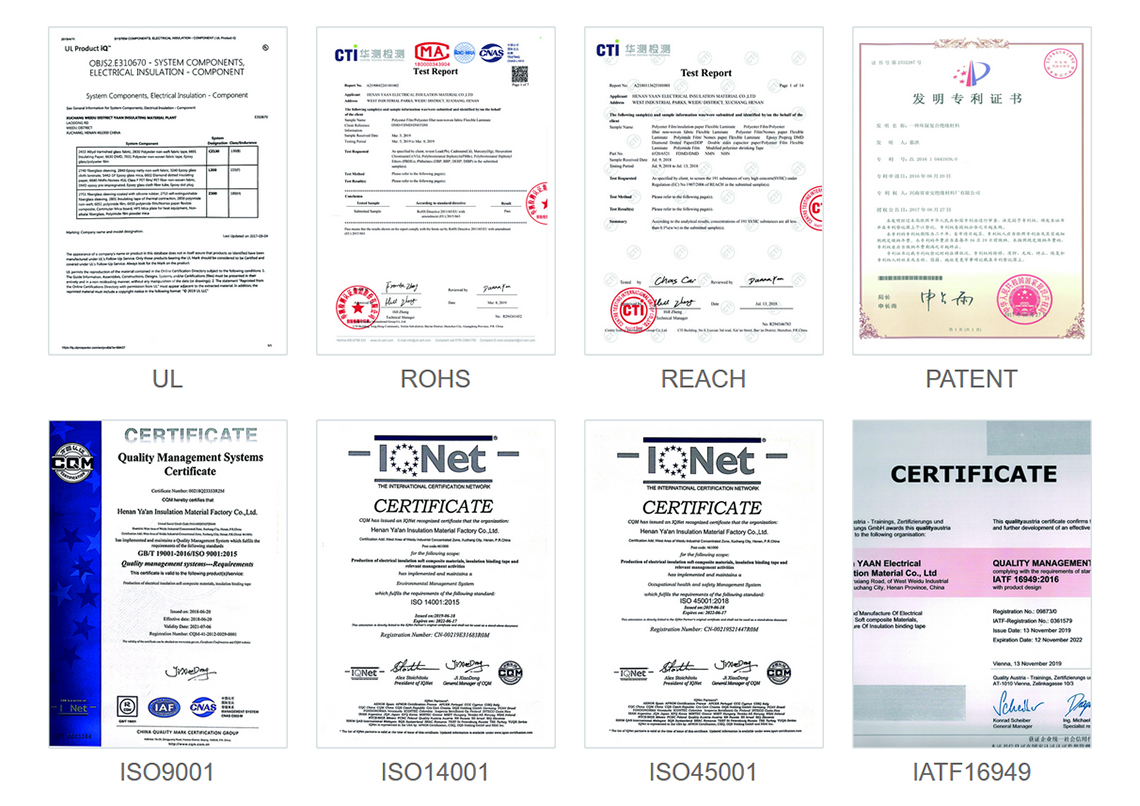

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates