Main Parameters:

Insulation class: B class (130 °C)

Color: Regular color is white

Width: 1000mm

Thickness: 0.2mm,0.25mm,0.3mm,0.35mm

Can be customized

Product Information

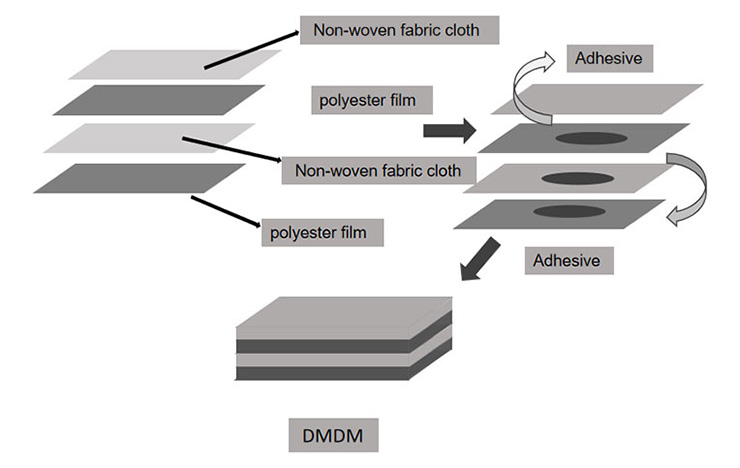

Description of DMDM Insulation Paper

DMDM insulating paper is four-layer flexible composite material which is composed of two-layer polyester fiber non-woven(D) and two-layer polyester film(M) overlapped alternately and glued together.

Four-layer DMDM insulating paper using polyester film and polyester fiber non-woven as raw materials, ensuring that the series products have excellent mechanical property, temperature and corrosion resistance, high rigidity, hardness and toughness, and good chemical resistance and oil resistance.

DMDM has higher mechanical strength and electrical property compared with DMD with a same thickness.

Features of the DMDM Insulation Paper

1.Insulation class: B class (130 °C)

2. Color: Regular color is white

3. Width: 1000mm

4. Thickness: 0.2mm,0.25mm,0.3mm,0.35mm, Can be customized

5. It has been approved by UL (NO.: E310670) ,ROHS and REACH test.

6. Ya'an insulation production of 6631 / B grade DMDM insulation paper products for UL recognized electrical parts and components. UL file number: E310670. Under the UL electrical insulation system (OBJS2) -B-class insulation system. The insulation paper in line with the EU RoHs standard testing test 2002/95 / EC directive, is lead-free, nickel-free, cadmium-free green electrical products.

Technical Parameters

| Item | Unit | Requirement | ||||||||||

| Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | ||

| Thickness tolerance | mm | ±0.02 | ±0.025 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.035 | ±0.04 | ±0.045 | ||

| Grammage | g/㎡ | 140 | 190 | 220 | 260 | 300 | 350 | 425 | 500 | 560 | ||

| Grammage tolerance | % | ±20 | ±28 | ±33 | ±39 | ±45 | ±52 | ±63 | ±75 | ±84 | ||

| Tensile strength (MD) | MD no bending | N/10mm > |

80 | 120 | 140 | 180 | 190 | 270 | 320 | 340 | 370 | |

| TD no bending | 80 | 105 | 120 | 150 | 170 | 200 | 300 | 320 | 350 | |||

| MD after bending | 80 | 105 | 120 | 150 | 170 | 200 | 300 | 320 | 350 | |||

| TD after bending | 70 | 90 | 100 | 120 | 130 | 150 | 200 | 220 | 250 | |||

| Elongation | MD no bending | % | ≥15 | — | — | |||||||

| MD after bending | ≥10 | ≥5 | ≥3 | |||||||||

| TD no bending | ≥20 | — | — | |||||||||

| TD after bending | ≥10 | ≥5 | ≥5 | |||||||||

| Breakdown voltage | KV ≥ |

6 | 7 | 9 | 10 | 12 | 15 | 18 | 20 | 22 | ||

| Bonding strength at room temperature | — | No Delamination | ||||||||||

| Heat affected(155±2℃) 10min | — | No Delamination, no bubble, no adhesive flow | ||||||||||

| temperature index (T·1) | — | ≥130 | ||||||||||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

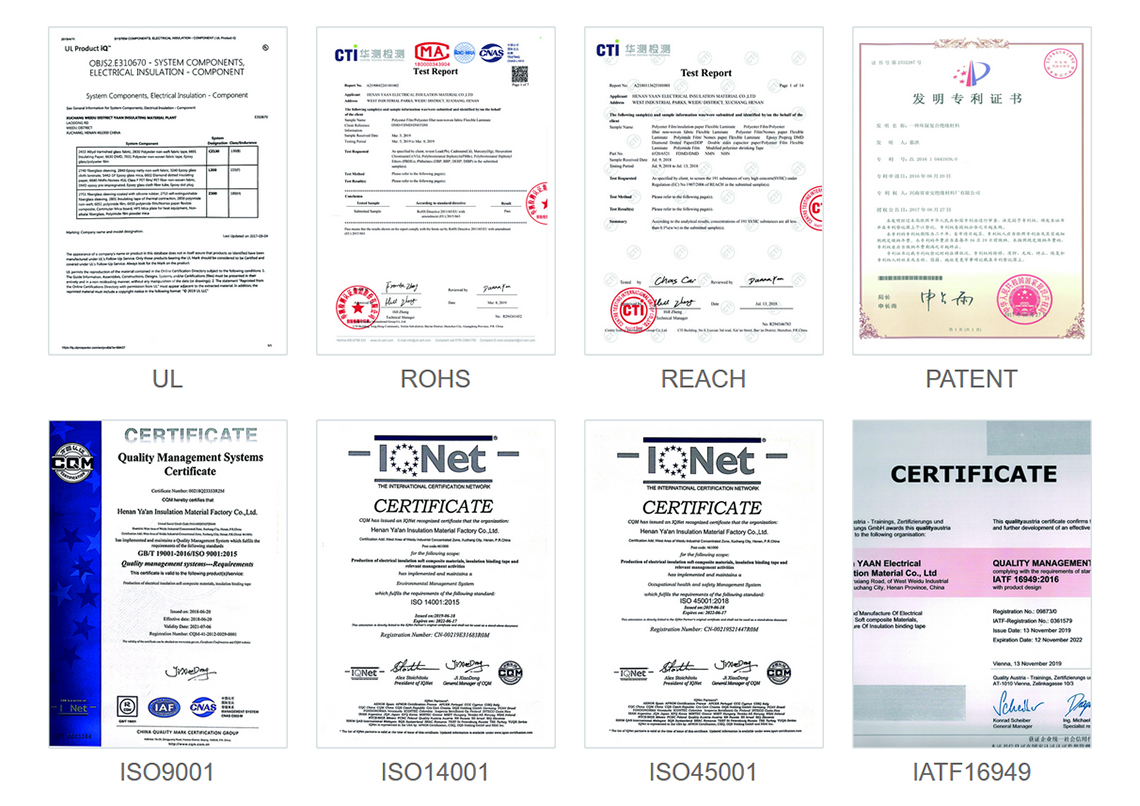

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates