Main Parameters:

Insulation class: B/F class (130°C/155 °C)

Color: Blue, green, white and pink

Width: 10-1000mm

Thickness: 0.088-0.5mm

*Can be customized

Product Information

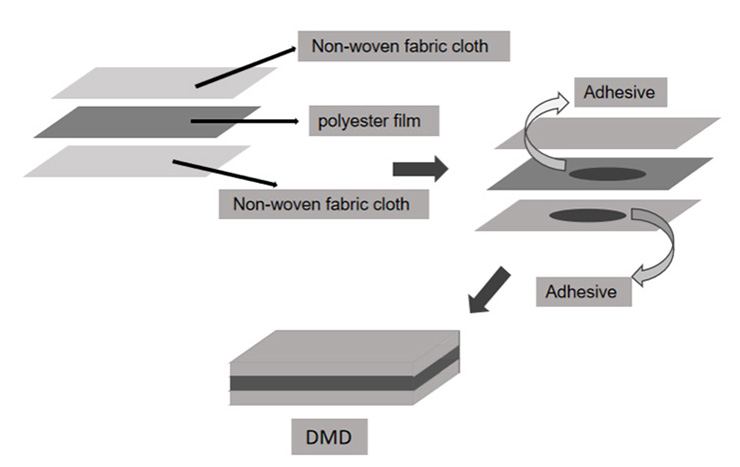

Brief introduction of the DMD insulation paper

DMD flexible laminates is a three-layer flexible composite material. It is made by bonding both sides of non-woven polyester fabric with polyester films with F-grade or B-grade adhesive.

About the Yaan Polyester Film: It is made from Polyethylene terephthalate by casting & Biaxially oriented. It is widely used for the end wrap insulation, liner insulation of electrical oils, electromagnetic wire wrap insulation, cable wrapping on motor, transformer or other electrical appliances.

Used for electrical insulation, DMD Composite Paper is economical and versatile. This three-layer constructions ensures the material offers good mechanical and dielectric strength while still being able to be impregnated by insulating varnishes.

Main features of this DMD insulation paper:

1. Economical type of electrical insulation material for medium temperature machines.

2. Made from Polyester Film with a non-woven polyester fabric on both sides.

3. Excellent electrical and mechanical properties with a smooth surface finish.

4. Available in a selection of thicknesses by the roll, linear metre or a custom cut tapes and parts.

About our DMD insulation paper, it is available in a selection of thicknesses. DMD’s construction ensures it provides good electrical strength. Specific breakdown voltage ratings vary depending on overall thickness, you can choose you need according the parameters on the chart:

Technical Parameters

| Item | Unit | Requirement | |||||||||

| Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | |

| Thickness tolerance | mm | ±0.02 | ±0.025 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.035 | ±0.04 | ±0.045 | |

| Grammage | g/m2 | 140±20 | 190±28 | 220±33 | 260±39 | 300±45 | 350±52 | 425±63 | 500±75 | 560±84 | |

| Film nominal thickness | um | 50 | 75 | 100 | 125 | 150 | 190 | 250 | 300 | 350 | |

| Tensile strength | MD no bending | N/10mm | ≥80 | ≥120 | ≥140 | ≥180 | ≥200 | ≥270 | ≥320 | ≥340 | ≥370 |

| MD after bending | ≥80 | ≥105 | ≥120 | ≥150 | ≥170 | ≥200 | ≥300 | ≥320 | ≥350 | ||

| TD no bending | ≥80 | ≥105 | ≥120 | ≥150 | ≥170 | ≥200 | ≥300 | ≥320 | ≥350 | ||

| TD after bending | ≥70 | ≥90 | ≥100 | ≥120 | ≥130 | ≥150 | ≥200 | ≥220 | ≥250 | ||

| Elongation | MD no bending | % | ≥15 | ≥5 | ≥5 | ||||||

| MD after bending | ≥10 | ≥5 | ≥3 | ||||||||

| TD no bending | ≥20 | ≥5 | ≥5 | ||||||||

| TD after bending | ≥10 | ≥5 | ≥2 | ||||||||

| Breakdown voltage | No bending | KV | ≥6 | ≥7 | ≥9 | ≥10 | ≥12 | ≥15 | ≥18 | ≥20 | ≥22 |

| Delamination | — | No Delamination, no bubble or other defects | |||||||||

| Heat affected(155±2℃) 10min | No Delamination, no bubble, no adhesive flow | ||||||||||

| Long-term heat resistance | ≥130 | ||||||||||

| (temperature index TI) | |||||||||||

| Weight and area conversion | m2/Kg | 6.37 | 5.21 | 4.41 | 3.82 | 3.37 | 2.86 | 2.29 | 1.97 | 1.73 | |

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates