Main Parameters:

Model: 6020,6021

Insulation class:E Class (120℃)

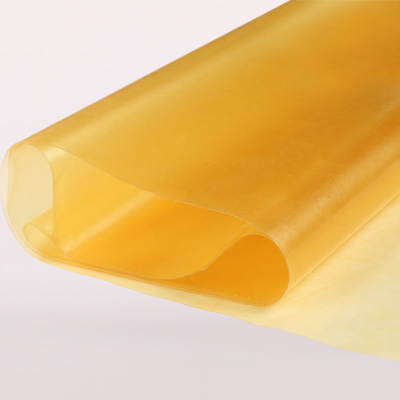

Color:6020 transparent,6021 translucent

Width: 1010mm

Thickness:0.025mm-0.35mm

Product Information

Description of Polyester Film:

Polyester film - (PET Film) exhibits superior strength, heat resistance, and excellent insulating properties. The unique qualities of Mylar® film (PET Film) created new consumer markets in magnetic audio and video tape, capacitor dielectrics, packaging, and batteries.

Polyester Film is made from Polyethylene terephthalate by casting & Biaxially oriented.

About the polyester film, Yanan has two different types:

6020-Polyester Film For Electrical Insulation (Transparent)

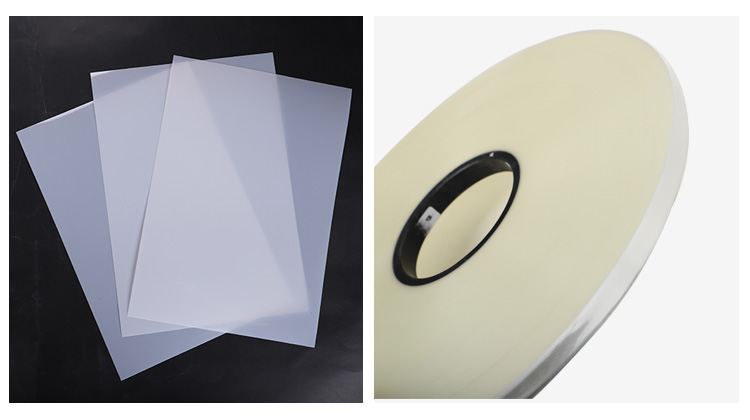

6021-Polyester Film For Electrical Insulation (Milky white)

The different between the 6020 and 6021:

6020/6021 polyester film is biaxially oriented polyethylene terephthalate (PET)film.6020 is transparent film,6021 is milky white.

6020 polyester film always as a laminate with other substrates.6021 can be used as an electrical insulation directly, it has good dielectrical and high mechanical properties.

Features of the Polyester Film

—Good mechanical properties and folding tolerance

—Resistant to oil, fat, dilute acid and alkali, most solvent.

—Has excellent temperature tolerance.

—Low gas and vapor permeability, and good resistance to gas, water,

oil and odor.

—High transparency and glossy, also can block ultraviolet ray.

—Can be directly used in food packing since it is non-toxic, unscented with good sanitary security.

—Model: 6020,6021

—Insulation class:E Class (120℃)

—Color:6020 transparent,6021 translucent

—Width: 1010mm

—Thickness:0.025mm-0.35mm

—The Class E 6020 transparent and 6021 translucent polyester film have been approved by UL (NO.: E310670) ,ROHS and REACH test.

Technical Parameters

| Item | Unit | Index value | ||||||

| Nominal thickness | um | 125 | 150 | 190 | 250 | 300 | 350 | |

| Thickness deviation | um | ±10% | ||||||

| Wide format | m | 1m, Special width can cut | ||||||

| Density | Kg/m3 | 1400±10 | ||||||

| Melting point | ℃ | ≥256 | ||||||

| Relative permittivity | 48Hz~62Hz | / | 2.9~3.4 | |||||

| 1KHz | 3.2±0.3 | |||||||

| Dielectric loss | 48Hz~62Hz | ≤3.0×10-3 | ||||||

| factor | 1KHz | / | ≤6.0×10-3 | |||||

| Volume resistivity | Ω·m | ≥1.0×1014 | ||||||

| Surface resistivity | Ω | ≥1.0×1013 | ||||||

| Electrolytic corrosion | Visual | / | A1 | |||||

| Stretched wire | % | ≤2 | ||||||

| Dimensional stability at high | Under tension | ≥200 | ||||||

| temperature | Under pressure | ℃ | ≥200 | |||||

| Thickness | um | 100~250 | >250 | |||||

| Tensile strength (MD or TD) | MPa | ≥140 | ≥110 | |||||

| minimum | ||||||||

| Elongation at break (MD or TD) | % | ≥80 | ≥80 | |||||

| minimum | ||||||||

| Shrinkage(lengthways or crosswise | % | ≤3.0 | ≤2.0 | |||||

| maximum | ||||||||

| Nominal thickness | um | 125 | 150 | 190 | 250 | 300 | 350 | |

| Power frequency electrical strength | V/um | 80 | 75 | 65 | 60 | 55 | 50 | |

| Long-term heat resistance | ℃ | T1≥130;End point standard: tensile strength maintains | ||||||

| the starting value10% | ||||||||

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are a manufacturer, We have more than 36 years experience in producing electrical insulation material.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Xuchang,Henan provience.

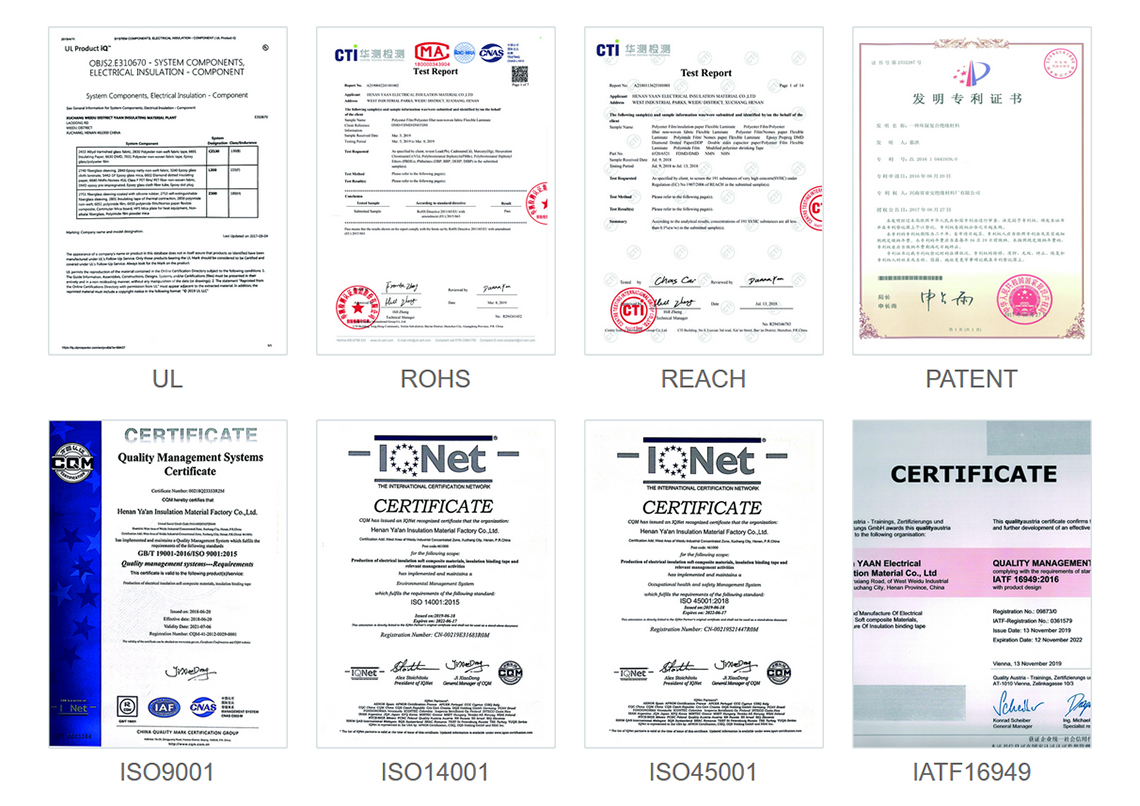

3.Q: Which certification do you have?

A: The plant has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

4.Q: Can i get a samples for free?

A: Of course we can sent you a sample for free, customers just need to pay a litter shipping change.

5.Q: How long is the delivery time?

A: Generally it is 5-15 days if polyimide film price is in stock, or it is 15-30 days.

Our production

Our Customer

Our Team

Our Certificates